Why Tensile Membrane Structures are the Future of Modern Architecture in India

India is undergoing a shift in how buildings are designed and utilized. Cities are modernizing, and people want spaces that look good, offer comfort, and are built efficiently. There is also a focus on reducing construction costs and minimizing environmental impact.

While concrete, steel, and other traditional materials are still in use, they are not the top choice for large rooftops. This is why tensile membrane structures are gaining popularity in the Indian market. These structures are lightweight, strong, and visually appealing. They are now commonly used in various commercial, public, and industrial settings.

What are Tensile Membrane Structures

Tensile membrane constructions are constructed with robust fabric stretched strongly over a grid of steel or a cable. This pulling is known as tension that serves to make the fabric strong enough to cover great areas.

The cloth is most often covered with special materials such as PTFE or PVC. These finishes make the fabric tough, water-resistant, and sun-sensitive. When the cloth is cemented in place, it becomes a concrete roof that is capable of absorbing the wind, rain, and heat.

These structures can be curved and smooth in shape. This makes buildings contemporary and fashionable. Tensile membrane is applied to the rooms, walkways, parking shades, stadiums, airport canopies, and open areas. They shield individuals against the sun and rain with the soft, natural light passing through.

Why Tensile Structures are Popular in India

The tensile membrane structures have gained popularity in India due to their smart combination of strength, beauty, and cost efficiency. They fit the weather conditions and the modern design of the country very well. In the public building sector, as well as commercial areas, tensile structures are increasingly being implemented in more projects due to their superior performance and construction speed.

Works Well in Indian Weather

India has strong sunlight, high heat, and heavy rains. Tensile membrane fabrics are made to handle all these conditions. They block harmful sunlight and help keep areas cooler. They are waterproof, so rain does not pass through. They also resist dust and moisture, which helps them last longer.

Saves Money and Time

These structures are much lighter than concrete or metal roofs, so they need less steel and smaller foundations, which helps reduce construction costs. They are also faster to build because many parts are made in factories and then installed on site, allowing projects to be completed more quickly.

Creates Open and Spacious Areas

Tensile structures can cover large areas without pillars in the middle. This is very useful in airports, stadiums, and halls where people need open space.

Looks Modern and Attractive

The fabric can be shaped into smooth curves and beautiful designs. It can also be made in different colors. This makes buildings look stylish and unique.

Environmentally Friendly

These structures use less material than traditional roofs. They also allow daylight to enter, which reduces the need for lights during the day. This saves electricity and supports green building goals.

Needs Less Maintenance

The fabric does not rust like metal. It also does not crack like concrete. It stays clean for a long time and needs only simple cleaning.

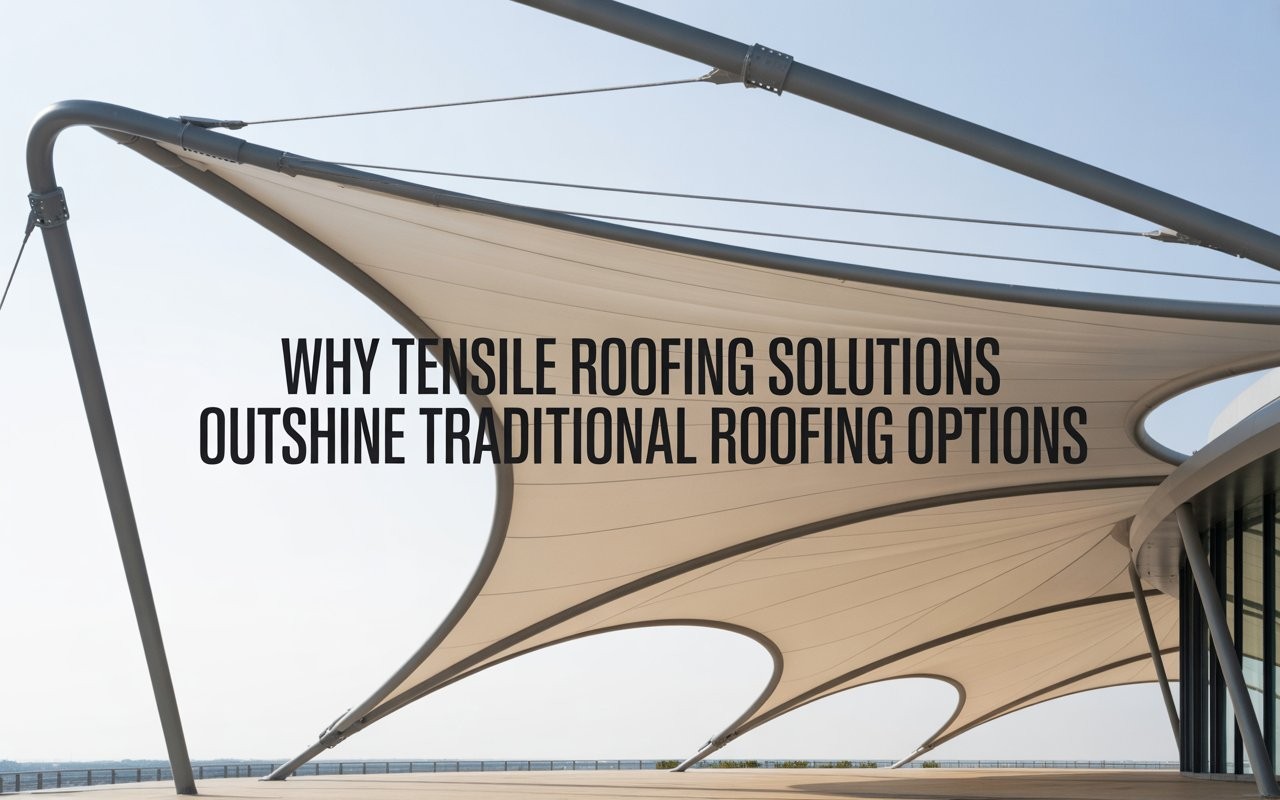

Read more on: Why Tensile Roofing Solutions Outshine Traditional Roofing Options

Where Tensile Membrane Structures are Used in India

Tensile membrane structures are now widely seen across India in many types of spaces. They are used for entrance canopies, covered walkways, seating areas, and open public zones. These structures are also common in malls, hotels, resorts, parking areas, exhibition centers, and convention halls, where large covered spaces are needed without internal pillars. Many public places also use tensile canopies to provide shade and protection from rain.

How Technology is Making Tensile Structures Better

Modern technology has made tensile membrane structures stronger and more reliable. Better fabrics are now available that last longer and resist fire and sunlight. Engineers use computer software to design the structure and test how it will behave in wind and rain. This makes sure the structure is safe and stable.

The fabric panels are cut and joined using machines, which gives accurate size and strong joints. Installation methods have also improved, allowing structures to be set up faster and more safely. Beyond performance and efficiency, these advancements also highlight how tensile architecture balances sustainability with visually striking design.

Why Tensile Membrane Structures are the Future

India needs to build solutions that are fast, affordable, and good for the environment. Tensile membrane structures meet all these needs. They are strong, beautiful, and suitable for Indian weather. They also help save money and time.

Tensile Membrane Structure is the best choice you can make in an attempt to have a strong and stylish roofing or canopy that will serve you for many years. Pressmach offers quality tensile membrane structures that are suitable for the climate of India. No matter if it is an airport, stadium, office building, or an industrial setup, Pressmach has the expertise and capability to offer quality structures.

Your Requirements

Related

Blogs

6790c3d8f29a2.jpeg)

65cf4d38697f9.webp)

65cf65f046eed.webp)

64afe3444467b.jpeg)

site office front view622f00119ba65.jpg)

6349487807893.jpeg)