The Future of AI in Prefabricated Construction

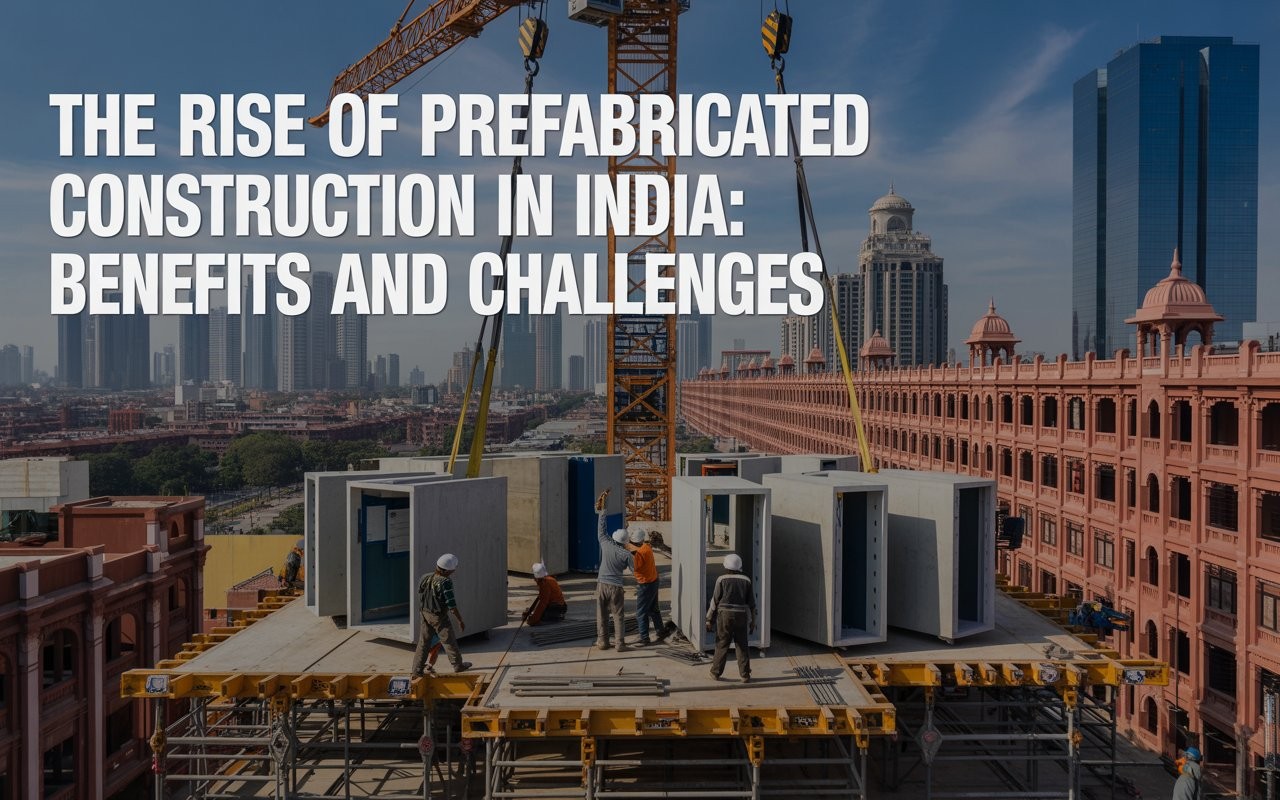

Artificial intelligence (AI) is making the building industry more efficient and open to new ideas than ever before. This is causing a revolution that will change everything. Adding artificial intelligence is particularly helpful for prefabricated construction, a method where building parts are made off-site and then put together where they belong. AI improves the accuracy of these designs, streamlines the management of the supply chain, and speeds up the assembly process, all of which cut down on excess waste and/or mistakes. Artificial intelligence can predict problems that might come up, make projects run more smoothly, and shorten their completion times by using machine learning methods. When artificial intelligence is added to prefabricated construction, it makes building processes more efficient while also improving quality and making them last longer. Artificial intelligence is getting better, and using it in pre-made construction could change the way buildings are built in the future, making them smarter, safer, and more efficient.

Key Concepts and Technologies

When it comes to prefabricated construction, Artificial Intelligence (AI) relies around fundamental concepts such as machine learning, robotics, and data analytics. Design processes may be optimized, prospective problems can be predicted, and efficiency can be improved with the use of machine learning techniques. By streamlining the manufacturing and assembly of prefabricated components, robotics helps to ensure precision while also minimizing the amount of labor that is required. Supply chain management, project schedules, and quality control are all areas that can benefit from the insights provided by data analytics. To improve the planning and execution of projects, technologies such as Building Information Modeling (BIM) connect with artificial intelligence. The building industry is undergoing a transformation as a result of these innovations, which are making prefabrication more intelligent, faster, and more environmentally friendly.

Check out our blog on: Advancements in Prefabricated Materials: What to Expect in 2025

Benefits of AI in Prefabrication

- AI integration in prefabrication improves construction in several ways. AI-driven design optimization reduces material waste and errors by planning precisely and efficiently. Machine learning algorithms analyze massive data sets to identify issues and streamline operations, ensuring project success.

- Second, AI-powered production and assembly robots improve precision and productivity. Automatic systems perform repetitive tasks with unsurpassed accuracy, saving manpower and expediting production. This speeds up project completion and improves quality.

- Third, AI improves supply chain management by delivering real-time inventory, logistics, and procurement analytics. This avoids delays and ensures material delivery.

- AI-enabled BIM integrates design, construction, and operating data into a single platform, improving stakeholder collaboration. This improves project collaboration and decision-making.

- AI optimizes energy use, reduces waste, and promotes eco-friendly materials, encouraging sustainability. Construction becomes more efficient, cost-effective, and ecologically friendly.

Challenges and Limitations of AI in Prefabricated Construction

As AI has transformed several industries, prefabricated buildings have followed suit. Challenges and restrictions must be addressed. Let’s look at some of them:

- Data Quality and Availability: Quality and availability of data are major obstacles. In the construction sector, high-quality data is often fragmented, inconsistent, or missing, which AI systems need to function. The AI's predictions and optimizations are limited.

- Lack of Standardization: In prefabricated construction processes and components, uniformity is lacking. Process standardization and predictability help AI thrive. Complex prefabrication procedures and materials might confuse AI systems, causing inefficiencies and errors.

- High Initial Investment and Maintenance Costs: Maintenance and initial investment expenditures are other issues. Implementing AI solutions demands significant technology, training, and maintenance costs. Smaller firms may struggle to justify such costs, limiting uptake.

- Integration with Existing Systems: Also difficult is system integration. System overhauls are expensive and time-consuming for many construction firms because their legacy systems are incompatible with AI.

- Human Factor: There's also human change resistance. Artificial intelligence-driven procedures may be unpopular with traditional workers and supervisors, hindering integration and limiting advantages.

Future Trends: How AI will Shape Prefabricated Construction

- Design Optimization: AI will change prefabricated construction. Design optimization is rising. AI algorithms examine massive data sets to design more efficient, sustainable, and affordable buildings. AI algorithms reduce construction times and material waste.

- Automation in Manufacturing: Industry trends include manufacturing automation.Precision and error reduction can be achieved via AI-driven robots and automation in prefabricated component production. Quality and consistency in building will improve. Intelligent maintenance will also depend on AI.

- Predictive Maintenance: By monitoring machines and components, AI can predict maintenance needs, eliminating costly breakdowns and delays. This enables smoother, more reliable building.

- Supply Chain Management: AI-optimized supply chain management will ensure timely material and component delivery. Artificial intelligence can forecast demand, manage inventory, and coordinate deliveries, saving time and money.

- Virtual and Augmented Reality Tools: AI-powered VR and AR tools will transform project planning and collaboration. With these tools, stakeholders can perceive projects in 3D, making it easier to spot and resolve challenges.

You May also like to read: Trends and Innovations in Prefab Commercial Building

Role Of Pressmach in Prefabrication Industry

Since 1985, Pressmach Infrastructure has been India's top prefab building business. We've been helping people from a wide range of fields for about 40 years. We have become the best in our field by providing high-quality services that describe who we are. The things that make us the best company for making modular buildings are:

- As a trustworthy prefab company in India, Pressmach only uses strong, long-lasting materials that won't rust when they build pre-engineered and prefabricated buildings. The prefab building materials from Pressmach would also be able to handle loads from the outside. They are perfect for marine tropical settings and bad weather.

- Every customer wants the best building at the best price. Pressmach knows what our customers want and can make pre-made designs and manufacturing packages that fit their needs. Being the best company in the prefab industry, Pressmach offers cost-effective movable structures, prefab buildings, and pre-engineering projects.

- The premade building from Pressmach would be able to stand up to loads and problems and still be perfect. Our processes for making, inspecting, and making sure of quality are so strict that every product that leaves the production center meets the quality standards they set.

Our focus is on clear working ideas because we want to do the best job possible. As being one of the best prefab companies in India that makes prefabricated buildings, we give perfect prefab solutions for many industries. As professionals, we are the best choice for you if you want to build something prefab in India.

Your Requirements

Related

Blogs

6790c3d8f29a2.jpeg)

65cf4d38697f9.webp)

65cf65f046eed.webp)

64afe3444467b.jpeg)

site office front view622f00119ba65.jpg)

6349487807893.jpeg)