Why is Prefabrication Called The Future Of Construction Methods

The Future

You might be surprised to know that buildings are either removed, renovated, or modified in about fifteen-twenty years in these modern times. Civil buildings involve a lot of expense in terms of approval, time of construction which adds to increased labor costs , increased interests due to the construction durations and destroyed using advanced technology, leading to added expenditure for the owner, besides creating a lot of waste material.

Why waste money, manpower, and energy & do we have alternatives?

Yes, there is a solution for this issue, and that is pre fab construction. The above issues along with environmental degradation resulted in the popularity and growth of modular construction methods. A reason why prefabrication is called the future of construction methods.

The Construction Industry is going greener. Know why? - Forbes

Pre-engineered modules used for the construction of simple buildings to skyscrapers have transformed the modular construction sector altogether.

Why Modular Construction is Replacing Traditional Construction Methods?

Prefabricated or modular construction offers excellent benefits that make it an ideal choice. Moreover, brick-and-mortar structures cause excessive expenses, loads of wastage, and labour requirements.

The factors that led to the downturn in the acceptance of concrete buildings include:

1. Difficulty in Future Alterations

Technical evolution is happening at a lightning speed nowadays. Novel construction patterns and unique requirements are appearing from nowhere every month. Consequently, construction patterns, designs, and appearance are becoming obsolete faster than before.

The owner will have to undertake an expensive renovation or replace the structure with a new one to meet the requirements of the time. The cost of raw materials for construction is also going up day by day, leading to exorbitant expenses for the renovation/ replacement of the structure. On the other hand, a modular structure can be replaced or renovated the way you want quickly. The complete activity would take up to a few days or weeks.

2. Demolition is a complex and costly affair

Demolition would be required for erecting a new structure in place of an old one. It is not an easy process. It would be more complex if the building were located among other facilities. A specialized destruction team will have to be hired for the task. It would be a highly expensive and intricate process.

The demolition team would take days or months for formulating the procedure for the specific building. Delaying the construction of the new structure further. Removing a modular building is a simple thing. The team would arrive, discuss the requirement, and dismantle it in a few days. No need for a well-defined demolition or a complex formula.

3. Waste Materials Harmful to the Environment

Demolition of a brick-and-mortar building would create a lot of dust and accumulation of waste materials. The waste from the concrete structure is harmful to the environment and hence has to be disposed of properly. Therefore, the owner should find a solution for waste disposal post the destruction or demolition of the building. A costly affair again!

Prefabricated and modular structures can be dismantled without any issues. The components can be reused or recycled—no need of paying additional for waste management or any waste material that is harmful to the biosphere.

4. Relocate Anywhere

Can you relocate a concrete structure? Not possible, right? What would happen if the authorities ask you to remove the structure? Or if you want to move to a new location that offers better business prospects. You can either abandon the building or demolish it.

The modular structure can be relocated to any place without much difficulty. The team from the pre-engineering construction would arrive at your place, dismantle the structure, move it to the new location, and construct it there. It is such a simple process. One of the main reasons is making modular construction the future of construction methods.

5. Buy Back Option

You don’t have to demolish the prefabricated structure, like a concrete building, even if the structure is obsolete and not in use anymore. We offer exclusive buyback options for our clients.This option to sell the prefabricated structure back to us will save you money. A guaranteed buyback of 20%, which can go up to 40% is what we offer. Making it more beneficial to choose prefab structure from Pressmach. Our team would assess and offer the right price for the school, factory, commercial centre or any other structure constructed by us, which is not being used.

Know more about Buyback Options & Benefits

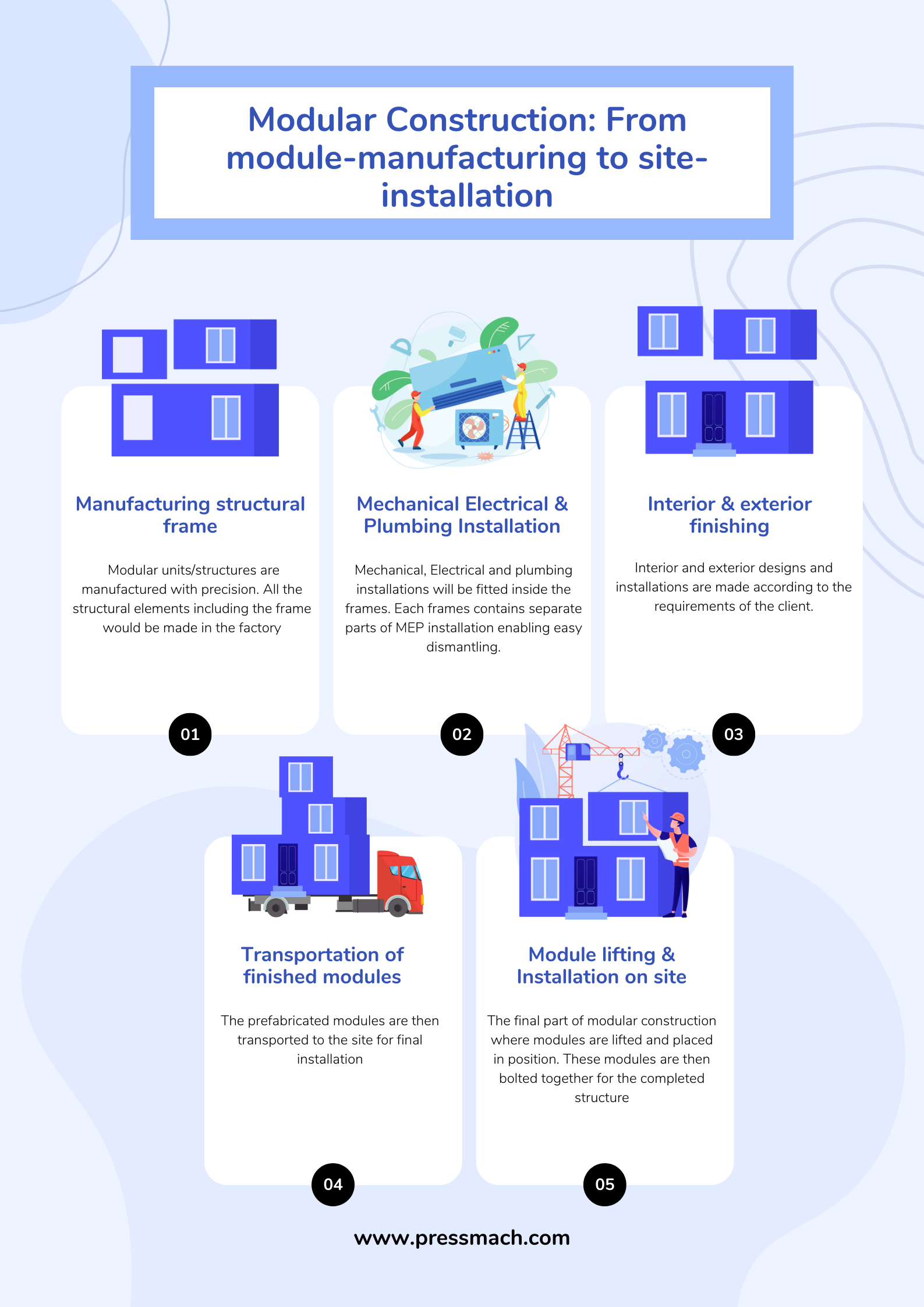

How does modular construction work?

Modular construction is the practical or “adult” version of LEGO toy blocks. It is exactly similar to the way blocks are assembled by kids. Construction of buildings with modular pieces is as simple and easy as that.

The modular construction process involves

- Calculation: The construction possibility would depend on the space availability. Unlike a concrete structure, modular construction can be undertaken even in limited space also. The space availability, design requirements, and structural specifications would be discussed with the client.

- Design: The design would be finalized based on the client’s suggestions and requirements. Precise calculations are the essence of efficient modular construction. Expert professionals would undertake accurate measurements and design the structure based on that.

- Manufacturing: Modular units would be manufactured with precision. All the structural elements including the frame would be made in the factory. It would be transported to the worksite for assembly and installation.

- Construction: The modular structure would be constructed at the site. Assembling of frames, insulation of walls and floors, installation of dry walls, and laying out of floors are included in the construction process. Once the structure is ready, the expert team would visit and suggest the finishing touches, interior design elements, etc.

Also Read - Building materials used for modular construction by Pressmach

Benefits & challenges of modular construction

Let’s see the benefits and challenges of modular construction, beginning with the benefits or advantages of opting for modular structures.

Benefits

- A quick construction process helps in saving time

- Climatic conditions will not delay the construction process. Hence, it can be completed in the promised schedule

- Cut down on labour costs with modular construction

- There would not be any clutter in the worksite as the modules are manufactured at factory

- No or reduced waste as almost everything used for pre-engineered and modular construction can be reused or recycled

Challenges

- Only a limited variety is available

- Mass production may affect quality if procured from unreliable manufacturers (making it advisable to hire only a trusted modular construction service provider)

- Competitive designers and engineers with skills in the field are mandatory

- The transportation cost of modular blocks needs to be considered

The End

Prefabrication is called the future of construction methods mainly owing to the reasons stated above. Opting for a prefabricated or modular structure would be the most cost-effective and time efficient option for building construction.

Go Green! With sustainable construction methods from Pressmach Infrastructure Pvt Ltd

Talk with the experts. Dial +91 9884085510

Your Requirements

Related

Blogs

6790c3d8f29a2.jpeg)

65cf4d38697f9.webp)

65cf65f046eed.webp)

64afe3444467b.jpeg)

site office front view622f00119ba65.jpg)

6349487807893.jpeg)