Different Types Of Modular Construction: Advantages & Applications

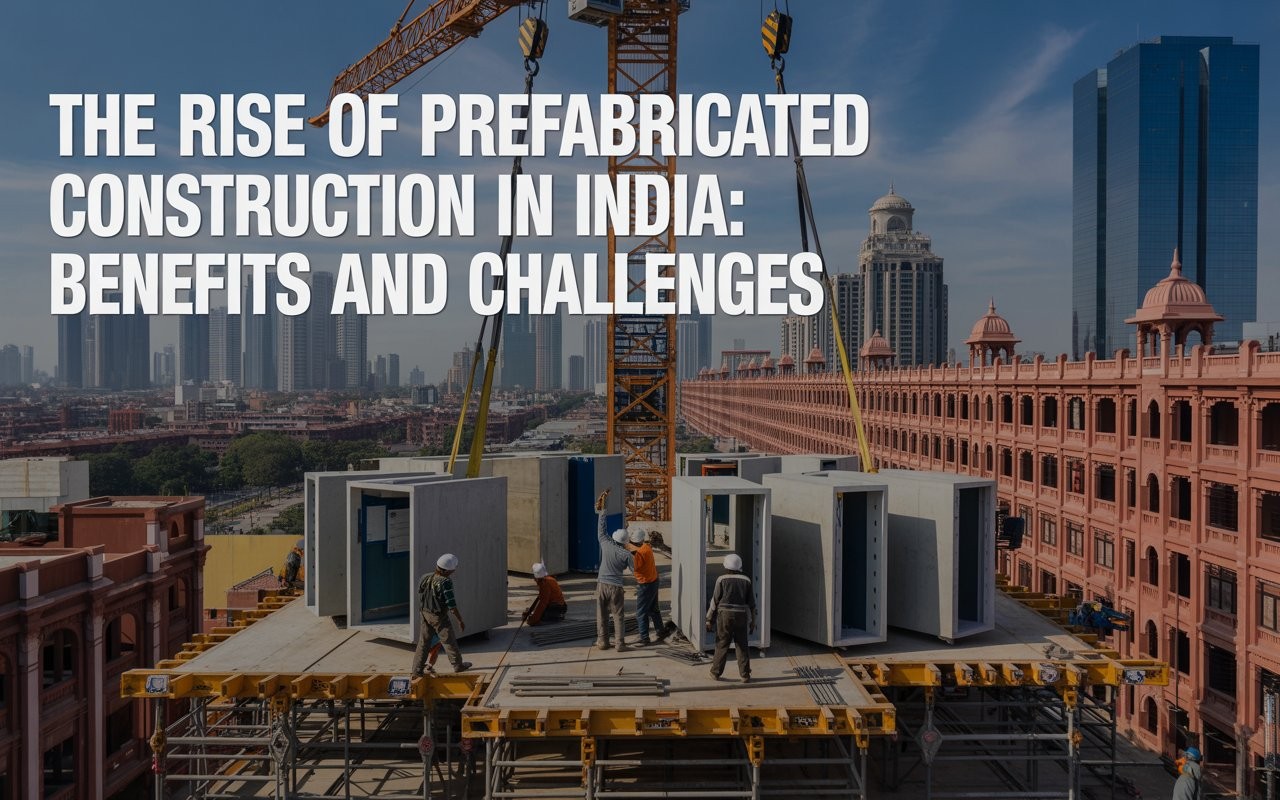

Modular building techniques have become a game-changing option in an era where speed, sustainability, and efficiency are critical in construction. This blog will look into the numerous Types of modular buildings, analysing their unique traits and the benefits they provide. Whether you're a construction professional seeking innovative approaches or simply curious about the future of building. This blog explains in detail about the different types of modular construction with examples, their advantages, applications, and their differences between traditional and prefabricated construction

What is Modular Construction?

Modular building construction is a building approach that takes place in controlled factory conditions rather than the standard "stick-built" method, where structures are assembled piece by piece on-site. Buildings are constructed in "modules," or independent portions, in modular construction.

The same building regulations, materials, and standards apply to modular construction projects as to traditional construction projects. The most cutting-edge site-built facilities use completed modules that are delivered to the construction site and installed to seamlessly interact with one another while maintaining the original design intent and architectural standards.

How are Modular buildings different from Prefabricated buildings?

| Aspect | Modular Construction | Prefabrication |

| Definition | Assembly of repeating modules in a factory setting. | Construction work done off-site before assembly. |

| Customization | Changes or customizations can be challenging. | Allows for flexibility in design and customization. |

| Standardization | Modules often share standardized designs. | Can involve various components, not necessarily repeating. |

| Applications | Ideal for projects with repetitive room layouts (e.g., schools, hospitals). | Suitable for a wide range of construction projects. |

| Examples | Healthcare facilities, educational buildings, offices, and residential structures. | Structural elements, wall panels, and more. |

| Planning and Efficiency | Requires meticulous planning due to module repetition. | Offers flexibility but may have production limitations. |

| Project Suitability | Well-suited for projects requiring speed and cost efficiency with repeated designs. | Suitable for various construction scenarios. |

Know about the distinctions between prefabricated and modular construction? Click to read about the Difference Between Prefabricated and Modular Construction!

Benefits Of Modular Construction Over Traditional Construction

Numerous benefits of modular construction make it an appealing option for many kinds of construction projects.

Remote Location Service: In remote locations where conventional on-site building can be costly and time-consuming, modular construction is helpful. It offers quick and affordable solutions for sanitary and medical facilities in difficult environments.

Sustainability: By reducing waste, modular building fosters sustainability. Compared to conventional site-built homes, standardised designs, and effective material use can reduce construction waste by up to 90%. Through this environmentally beneficial method, less cardboard, shrink wrap, and wood pallet waste is disposed away.

Flexibility: Modular structures can be expanded, changed, disassembled, moved, or renovated to accommodate changing needs. This results in a decrease in the need for raw materials and a reduction in energy usage, making it a sustainable decision.

Quality Control: Using a combination of conventional construction methods and stringent third-party inspections and testing, modular construction upholds high standards. In many cases, modular buildings outlast site-built structures in terms of durability while also adhering to local, state, and federal standards and codes.

Structural Integrity: Structural Insulated Panels (SIPs), which provide improved thermal performance, resistance to dampness and cold, and increased longevity as compared to conventional building materials, are widely used in modular units. Additionally, these panels enable the smooth integration of modular pieces with existing structures.

Get an in-depth idea about how fast modular construction is compared to traditional construction. Read more at https://www.pressmach.com/blog/how-prefabrication-fuelled-the-worlds-fastest-construction-projects

The Different Types of Modular Construction

Open Modular Construction: Open modular construction uses standardized building parts and structures for compatibility and adaptability. It uses prefabricated modules that can be quickly put together and modified, enabling effective construction and changes. Through the dissemination of designs, technology, and best practices throughout the building sector, this strategy promotes collaboration, innovation, and sustainability. By lowering waste, increasing energy efficiency, and making future renovations simpler, it improves cost-effectiveness, scalability, and environmental friendliness.

Closed Modular Construction: Closed modular construction is a type of construction in which complete rooms or modules are constructed off-site in a carefully supervised manufacturing setting. These modules are built with all the necessary HVAC, plumbing, and electrical wiring already installed and connected.

This method has various advantages, making it particularly useful for large-scale projects like homes, apartments, and hospitals. Firstly, the fact that the work is being done indoors prevents weather-related delays and guarantees steady progress. Working under regulated circumstances also boosts output and facilitates greater quality control.

Applications of modular construction: When it comes to quality, design, and unit size, modular building has come to be associated more and more with permanent structures than with temporary ones.

Here are some of the applications of modular constructions:

- Workplaces

- Residences

- Sports arenas

- And various other building types

The present wave of modular construction demonstrates its adaptability and effectiveness in a wide range of applications, offering cost and time savings while maintaining quality standards comparable to traditional construction methods.

Examples of modular buildings

Mobile offices: These facilities offer a mobile workstation with standard office services, such as utilities and electricity. They are very adaptable, which is advantageous for businesses whose office operations are temporary. They can also aid in lowering the company's overhead costs. For independent workers and contractors, mobile offices are perfect.

Portable Offices: Portable offices are easily transportable structures that may be moved using a forklift or vehicle. They may be easily disassembled and used for temporary space requirements at events, building sites, and festivals.

Prefabricated Booths: Prefabricated booths are compact, adaptable buildings with off-site manufactured walls and roofing that are constructed on-site. They have numerous design options and can have amenities like internet, sinks, and HVAC. Both temporary and permanent installations are appropriate for them.

Prefabricated Shelters: Prefabricated shelters provide a safe and cozy way to design outdoor areas that offer defense against a variety of environmental factors like bad weather, pollution, trash, and rain. These shelters can be built to exact specifications due to their high degree of customization.

The bus shelter, which was created exclusively for commuters, is an example of a prefabricated shelter. To give passengers a specific area to wait for their trips, these shelters are constructed in strategic locations at bus stops and terminals. They typically have a roof that provides enough ventilation and defence against heat, smoke, dust, and rain.

Prefabricated Garages: Prefabricated garages are modular constructions with multiple car capacity and automatic doors that are used to store vehicles. They provide less expensive and time-consuming alternatives to building a permanent garage.

Conclusion

In short, modular construction offers a wide array of building types, each tailored to meet specific needs. Modern needs, such as those for speed, sustainability, and adaptability, are addressed by modular construction, which is more than just a construction technique. Modular building is at the forefront of the construction industry's ongoing evolution, providing cutting-edge solutions for the structures of today and the future.

Explore our innovative solutions for faster, sustainable, and flexible building projects. Make an appointment to discuss your needs for modular building with Pressmach Infrastructure.

Connections between modules are often made using plates that are connected using bolts. The modules can be safely unhooked at a height thanks to the employment of special lifting frames. A variety of cladding materials can be pre-attached or fitted on-site, and modules can be produced with integral balconies.

Your Requirements

Related

Blogs

FAQ's

Connections between modules are often made using plates that are connected using bolts. The modules can be safely unhooked at a height thanks to the employment of special lifting frames. A variety of cladding materials can be pre-attached or fitted on-site, and modules can be produced with integral balconies.

Low resale value, land and location restrictions, little customizability, and tricky financing.

Given the proper maintenance and building style, the majority of permanent modular buildings can endure 35 years, 50 years, or even centuries.

Yes, generally speaking. A significant factor is the cost and availability of on-site labour.

A structure erected using the modular building process will survive just as long as a traditional site-made structure, if not longer.

6790c3d8f29a2.jpeg)

65cf4d38697f9.webp)

65cf65f046eed.webp)

64afe3444467b.jpeg)

site office front view622f00119ba65.jpg)

6349487807893.jpeg)