What Is The Difference Between Precast And Prefabricated Buildings?

Prefabricated construction is the process of putting together prefabricated components to build industrial structures and then transporting them to their final destination. Manufacturing things in a pre-made cast or mould and then transferring them to the construction site for final assembly after curing in a controlled environment is known as precast construction. Both styles of building offer benefits and drawbacks.

Here are some common differences between prefabricated and precast buildings:

What is a prefabricated building?

A prefabricated building, sometimes known as a prefab house, is produced entirely in a factory. For example, pre-engineered steel construction framing will be fabricated in a factory, then trucked to the job site and placed as a gigantic erector there only.

Prefabrication is the process of creating all of the building's structural components in factories or other production facilities and then transporting them to the construction site. To complete the building's final structure, all of the components are simply assembled or sub-assembled.

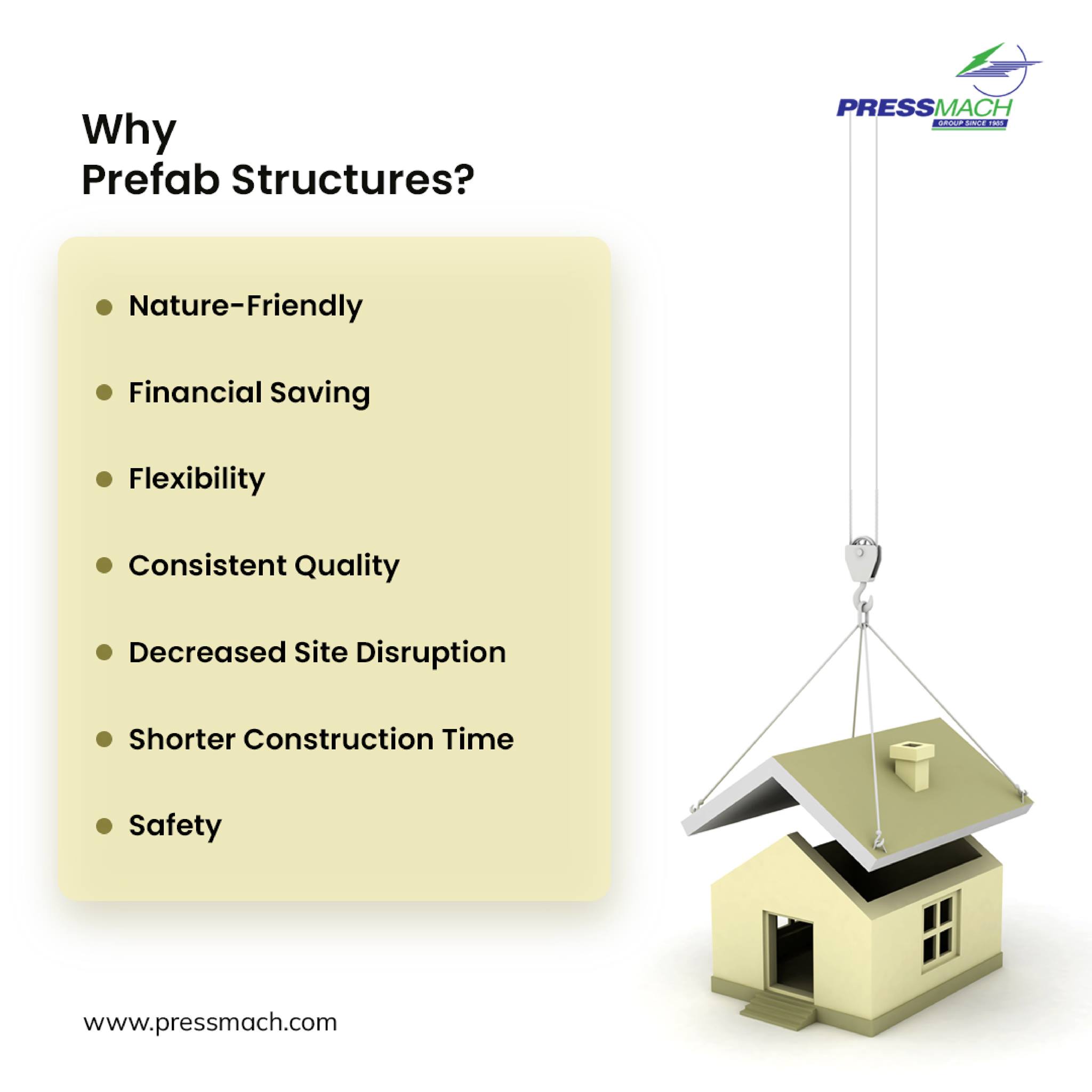

Benefits of prefabricated buildings

- Each of the building units in prefabricated construction can be readily disassembled and transported to a different location. This cuts down on the need for fresh materials, energy consumption, and overall construction time.

- Furthermore, the prefabricated construction process provides you with a great deal of versatility in terms of structural design, allowing you to customise your home to your exact specifications.

- Construction professionals do not have to worry about delays or interference from the weather, vandals, intruders, or other complicated problems because prefab procedures are applied indoors in a factory. Owners may speed the prefab construction process and reduce waste in this controlled, safe setting. Prefab is hence economical.

- The traditional on-site construction approach takes substantially longer to complete than prefabricated construction. Prefabrication, in many circumstances, takes less than half the time to complete a building as traditional methods.

- Prefab decreases the environmental impact in various situations. It can help to reduce pollution from construction projects in the air, water, and noise.

- Prefab is particularly useful for projects that require a high level of redundancy. This indicates that many of the rooms in the structure are similar or identical. Student housing, hotels, hospitals, and institutional buildings are all examples of this type of structure.

- Prefab can help you complete a project with a smaller staff as the industry deals with a talent shortage. Fewer individuals can get more work done because most of the job is done indoors with less strain. Workers view these locations as being safer than regular construction sites.

You can also check out this checklist before choosing a prefab company

What is a precast building?

Precast construction involves a type of concrete that is mixed, cast, and cured off-site, usually at a factory using reusable moulds. Precast concrete elements can be connected to create a complete structure. Wall panels, columns, beams, floors, pipes, stairwells, tunnels, and other structural components are commonly used.

Many buildings today use a combination of these construction methods, with structural steelwork, in-situ concrete, and precast concrete parts being used in some cases.

In terms of design, precast construction is limited. Due to the pre-determined nature of the moulds, this procedure allows for a few changes. Precast items lack the size, shape, layout, and other aspects that can be adjusted in prefabricated projects.

Making a component with precast construction takes longer. The parts are created in stages, with enough time for the mould to solidify completely. If the product dimensions differ from the mould measurements, additional time will be required to get the mould to the required size.

Read about, the benefits of having a prefab site office

Benefits of precast buildings

- Precasting is an excellent method for mass-producing similar components in huge quantities. Assume we're constructing a 3,000-unit affordable housing complex. We could then employ precasting to create all of the apartment's wall and floor slabs, which we could then lift into place and connect.

- It makes construction easier since it is done in a specially designed precasting yard or factory.

- Instead of being built at a height, the construction is done on the ground.

- It can be done inside a climate-controlled structure, avoiding issues like rain, dust, cold, and heat.

- For several repetitions of the same component, specialised formwork (moulds) can be produced.

- The liquid concrete could be made, moved, and poured using specialised equipment.

Concrete curing can take place in a controlled atmosphere.

As a result, precast components might have excellent quality. Construction can be done quickly because the components can be made ahead of time. Engineers must build each set of components after the preceding set has been completed in cast-in-situ construction, which takes time because concrete takes 28 days to attain full strength.

Wrapping up

Prefabricated buildings are the best option for those looking for flexibility, lower costs, and shorter construction time. On the other hand, if you are someone who is looking to construct a building with quality, durability, and a sturdy structure, precast is the way to go!

Your Requirements

Related

Blogs

6790c3d8f29a2.jpeg)

65cf4d38697f9.webp)

65cf65f046eed.webp)

64afe3444467b.jpeg)

site office front view622f00119ba65.jpg)

6349487807893.jpeg)